Fuel tanks often experience problems that can easily be rectified with the help of a diesel fuel polishing technician. Let Diesel Dialysis explain these issues and offer solutions in today’s post.

Can I Preserve Diesel Fuel I Bought Ahead of Time?

Is Fuel Polishing Really Effective?

Fuel Polishing Services for Grinding Equipment

A recent project for Diesel Dialysis involved a construction company located in South Jersey. Diesel Dialysis was hired to investigate an issue with a grinder that the construction company was having issued with each time it was used.

According to the construction company the grinder would run fine until the fuel level dropped below ¼ of a tank. The grinder would then lose horsepower and shut down due to low fuel pressure.

The company’s technicians would change the filters and then blow air back into the fuel lines to unclog the hoses. Once this was completed the grinder would run without any problems until the fuel tank dropped below ¼ of a tank. The same issues would then happen again.

The customer suspected that somehow mulch had gotten in the fuel tank and they called Diesel Dialysis to flush the tank.

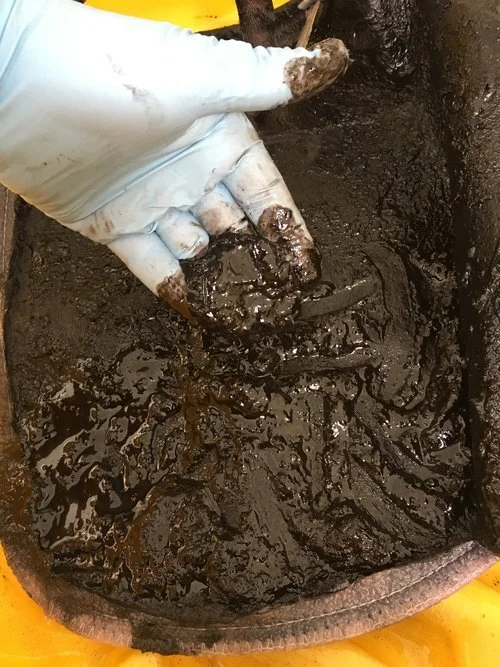

The crew from Diesel Dialysis set up a polisher and used long wands to reach various parts of the tank and wash out any debris. Diesel Dialysis found pieces of rubber collected in the primary filters of the fuel polisher. Further investigation found the rubber was part of a gasket that is installed on an inspection plate on top of the fuel tank.

Unfortunately, to access the plate the entire deck and belt system must be removed but they did not know they had this problem until we cleaned the tank. They did not know the inspection plates were there. There is also some minor evidence of microbial growth in the filter bags. The rubber gaskets likely failed due to age and prolonged exposure and contact with biodiesel. Biodiesel is corrosive and causes rubber seals and gaskets to swell until they fail.

Diesel Dialysis is dedicated to providing superior fuel polishing services to commercial and residential properties across the Delaware Valley and beyond. Contact us today to find out more about our services or to schedule an appointment for fuel polishing services.

Always Test Your Fuel (Even If It's New Fuel)

Fuel polishing and laboratory testing services from Diesel Dialysis help to ensure that the diesel fuel used in generators for commercial properties and oil used to heat residential properties is clean and meets ASTM specifications. Contrary to what many might believe, diesel fuel can be cleaned and should be cleaned for various reasons on a regular basis. If fuel is left too long in a tank, or a tank is never cleaned, bacteria and sediment can build up in the tank. Mold and sediment impact the effectiveness of the fuel when it is used and can drastically shorten the life of that fuel.

Diesel Dialysis was recently hired to evaluate the tanks and diesel fuel for a customer recently who received tainted diesel fuel. Diesel Dialysis was hired by the electrical contractor working at the job site who was installing three brand new 2.5-megawatt generators at a water treatment facility in New Jersey. Each of the generators has a 4,900-gallon tank that is only 22” deep and 40’ long.

Each of the three tanks received an initial fuel fill of 1,000 gallons.

The issue presented itself with the delivery of the fuel. The first tank was filled one day by just one truck. The second and third tanks were filled on a different day by a separate truck.

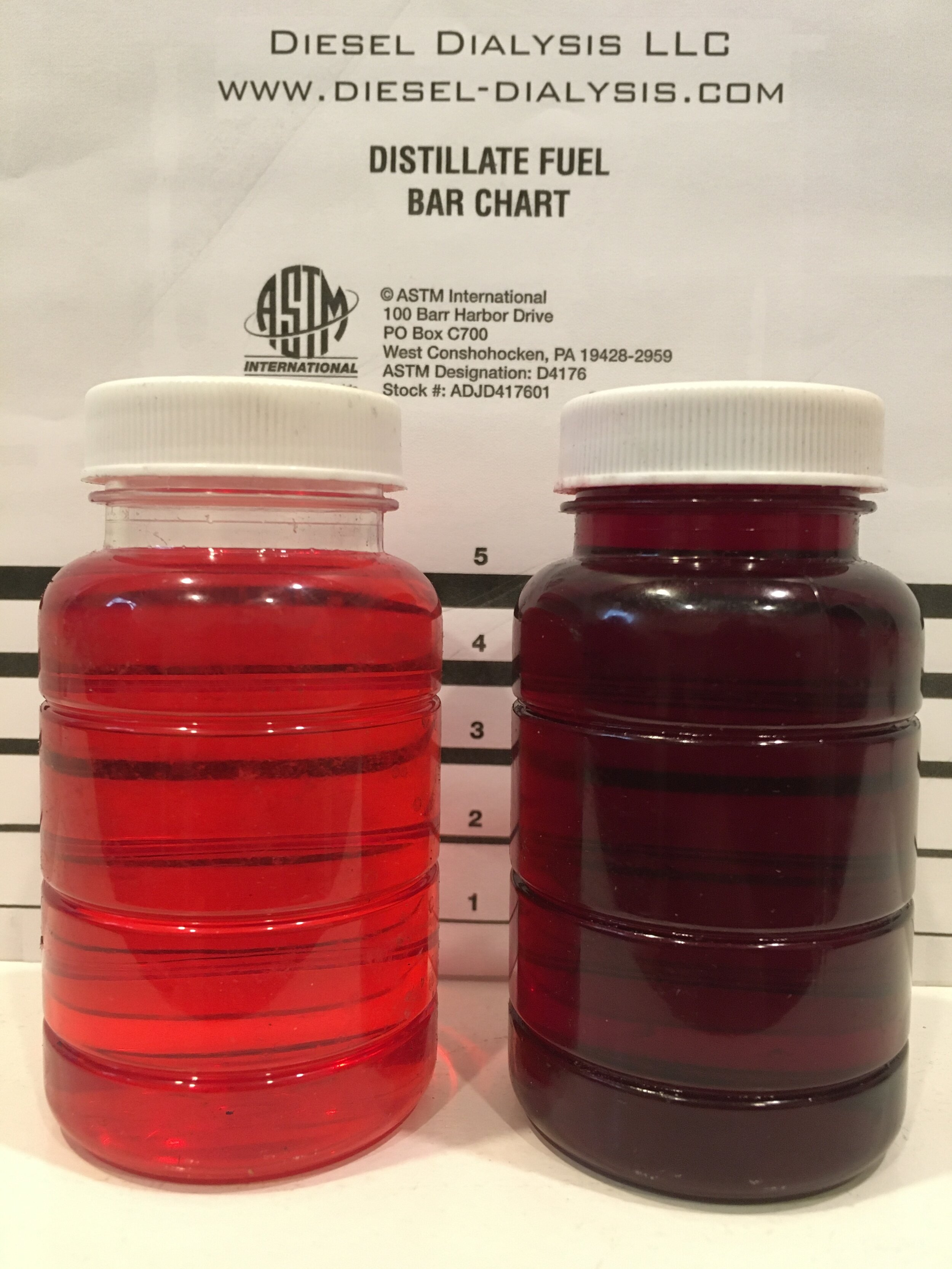

Diesel fuel is always clear when it is new, but it is dyed red when the fuel is purchased for “off-road” fuel. The reason for the red dye is to show that the fuel has not been taxed and it is not legal for “on highway” use.

The manufacturer of the generators would not start the generators to test them after the electrical contractor installed them. The electrical contractor and his client tried to prime the fuel systems. When they primed the systems they discovered water and very dark-colored fuel in the primary filters on 2 of the 3 new generators.

Diesel Dialysis owner Brian Hartley was called to the job site to investigate the problem. He inspected the tanks and took pictures because the generator manufacturer wanted to have the fuel polished and the tanks cleaned. They felt the fuel was dark in color because it was dirty.

Brian’s investigation found that the fuel distributed to tanks two and three were not dirty, the fuel was over-dyed at the refinery. The injection machine at the terminal failed and injected straight dye into the truck rather then the diesel fuel. The truck then came to the site and pumped it into the tanks. Because the fuel was new, the thought of sampling the fuel before hand use was not considered. It was only when the fuel system of the new generator was primed that the problem was noticed. Because the tank is so large and flat, it is now very hard to clean out.

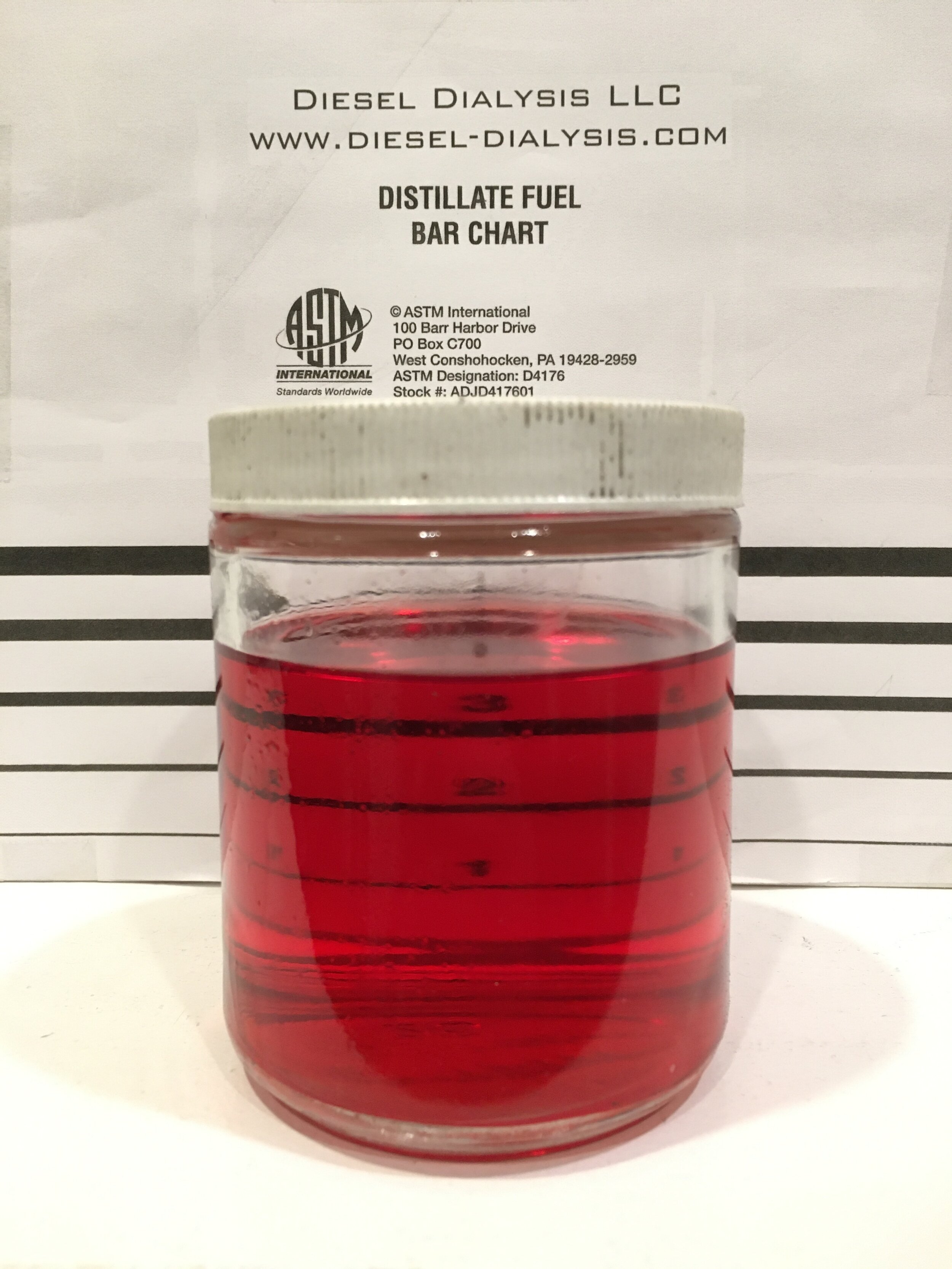

In order to resolve the problem the fuel had to be pumped out of the tanks and into an empty delivery truck. 500 gallons of brand new fuel was then flushed through the tanks from end to end. That fuel was also pumped out of the tanks into the waiting fuel truck. The tanks were then refilled with 1,000 gallons of new clear “on road” fuel in each.

The new clear fuel turned red because even after flushing the tanks there was still a lot of dye left in the tanks. Diesel Dialysis then polished the tanks with ultra high efficiency 3 stage filtration to remove any remaining water and contaminants. With a final filtration level of 1 micron and coalescing filter technology, we can ensure your fuel is clean and moisture free.

The moral of the story is to always take samples and test your fuel BEFORE you take delivery. Just because it is “new” it doesn’t mean it is good.

Contact Diesel Dialysis today to schedule an appointment for fuel polishing services at your business or residence.